The Light Beam One GUV Dynamic Sterilization Module is designed and planned according to its functions and divided into three types, which are explained as follows:

GUV Air Sterilization Module

The Light Beam One GUV has committed to developing air sterilization devices after recognizing that modern technology struggles to achieve the following three functions:

1. Reducing Infections: Current technology can only achieve a 99% bacteriostatic rate in 30 minutes but lacks sterilization capabilities. Air sterilization must account for airflow speed. For example, if the wind speed is 3.5 meters per second, bacteria and viruses remain in the air for a very short time. Therefore, the sterilization speed must be faster than the wind speed, making this a significant technical challenge.

2. Reducing Carbon Dioxide: Lower carbon dioxide levels equate to lower infection rates. Therefore, the Air Changes per Hour (ACH) must be high. For instance, a GMP cleanroom with ISO 8 requires 7-20 ACH, and ISO 6 requires over 30 ACH. However, current technology struggles to meet these requirements.

3. Deodorization: Volatile organic compounds (VOCs), including human body fluids,

sweat, and odors, can be decomposed. Hence, the ACH requirement needs to be

greater than 10, which current equipment finds challenging.

The Light Beam One air sterilization (GUV Sterilization Tunnel) operates on the sterilization formula K = I x T. By increasing the radiation energy more than a hundredfold, GUV significantly shortens the time needed to achieve effective sterilization.

Central Air Conditioning Air Sterilizer

GUV Circular Sterilization Tunnel

GUV Rectangular Sterilization Tunnel

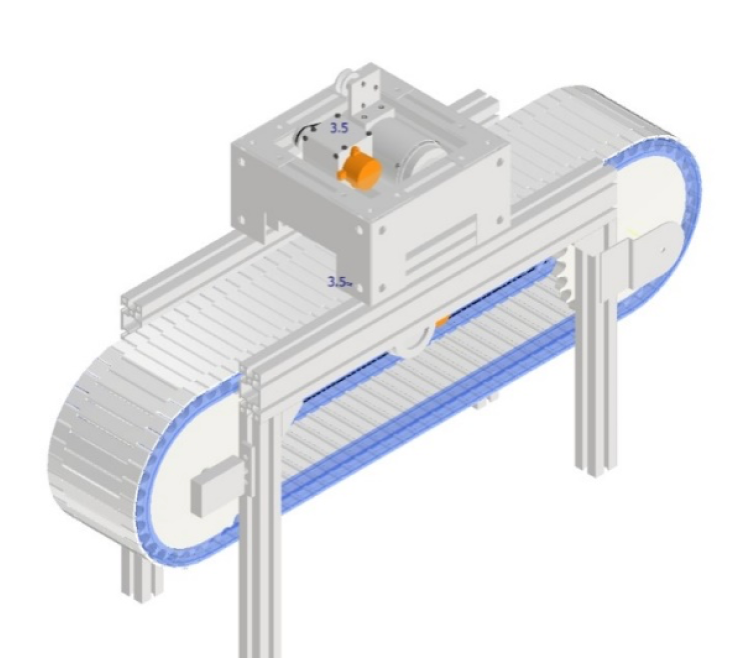

GUV Long-Shaped Sterilization Tunnel

The central air conditioning sterilization module uses GUV Dynamic technology to dynamically sterilize moving air. This device can be applied to air outlets in central air conditioning systems, open office spaces in company buildings, various air conditioning equipment, cars, airplanes, subways, buses, and other vehicles for air purification, disinfection, and deodorization. The module utilizes GUV ultraviolet sterilization lamps to instantly disinfect and sterilize the air passing through it. It boasts a compact size, high air flow, quiet operation, and easy installation.

Additionally, with its automatic switch design, it begins air sterilization immediately when turned on and shuts off automatically when not in use. The GUV light source is a low-power, mercury-free, environmentally friendly product. The GUV ultraviolet light is completely enclosed within aluminum housing, preventing any leakage and ensuring no ultraviolet pollution in the environment. This module is ideal for enclosed spaces, circulating air systems, medical environments, and the biotechnology industry.

GUV Water Sterilization Module

Current ultraviolet water sterilization technology commonly utilizes a UV LED matrix configuration. In order to maintain waterproofing, the UV light source is placed on the side of the water outlet, in line with the flow of water.

This design has several drawbacks:

1. The increased distance of light projection to the sterilization area weakens the sterilization effect.

2. The uneven light intensity distribution in the matrix requires increasing the LED power, which raises costs, consumes more energy, and is not environmentally friendly.

3. Higher power results in higher temperatures, causing hard water lime deposits on the quartz window and reducing its lifespan.

4. The presence of many non-dissolved minerals in water makes long-distance projection less effective.

GUV Dynamic utilizes high-reflectivity GUV Cylindric Reflection Technology to create multi-layered reflected light, achieving 99.99% sterilization with minimal power consumption.

The GUV Dynamic Water Sterilization Module uses GUV-LED to sterilize flowing water. According to the results from Super Laboratory Inspection Technology, it achieves a 99.99% sterilization rate against E. coli, making it suitable for handwashing, drinking water, and dishwashing applications.

The GUV Dynamic Water Sterilization Module employs GUVLED ultraviolet sterilization lamps to instantly sterilize water passing through the device. It features a compact size and easy installation, along with an automatic switch design that activates sterilization as soon as water flows through the module and shuts off when not in use. It is a low-power, mercury-free, environmentally friendly product. The UVC ultraviolet light is completely enclosed within stainless steel during operation, preventing any leakage and ensuring no ultraviolet pollution.

Long-Shaped sterilization tunnel

Research shows that the proportion of water dispensers with storage tanks is around 20-30% and is decreasing annually. This decline is due to the water in storage tanks not being fresh, poor taste, and the issue of secondary microbial contamination in the water pipes. The GUV Water Sterilization Module provides instant sterilization without the need for a storage tank and can be installed at the water outlet of the dispenser. This effectively improves water taste and eliminates secondary microbial contamination, making it the future trend for water dispenser sterilization.

GUV Surface Sterilization Module

The key technology of surface sterilization products lies in long-distance sterilization and overcoming the dead angles of light sterilization, especially the backlight areas of items, which are typically large dead angles.

Surface sterilization can be divided into two types:

1. Batch surface sterilization

2. Continuous surface sterilization

Light Beam One Technology understands this issue. GUV lamps not only provide high radiation intensity but also offer 360-degree scanning projection, achieving sterilization without dead angles.

The surface sterilization module uses GUV Dynamic ultraviolet light LED package, differing from traditional mercury lamps or UVC LEDs in the following ways:

1. GUV bulbs can save about 80% more energy compared to mercury lamps.

2. Mercury lamps produce ozone as a byproduct, which is harmful to the environment, while GUV does not produce ozone.

3. GUV LED package have low thermal efficiency, resulting in minimal heat impact on items and machinery.

4. The lifespan of UV LEDs is approximately 12 times that of mercury lamps.

5. The radiation direction is controlled, preventing secondary pollution.

6. The radiation light changes randomly in 360 degrees, ensuring sterilization without dead angles.

Continuous Surface Sterilization Module